The elegant idea of motor wheels for electric vehicles has not found wide distribution – it’s all the fault of the high cost and the problem of large unsprung masses. However, the idea of reducing electric motors to free up useful space inside the chassis does not leave the heads of automotive engineers. Hyundai has proposed a new solution by developing a UniWheel system with a spaced motor and a step-down gearbox.

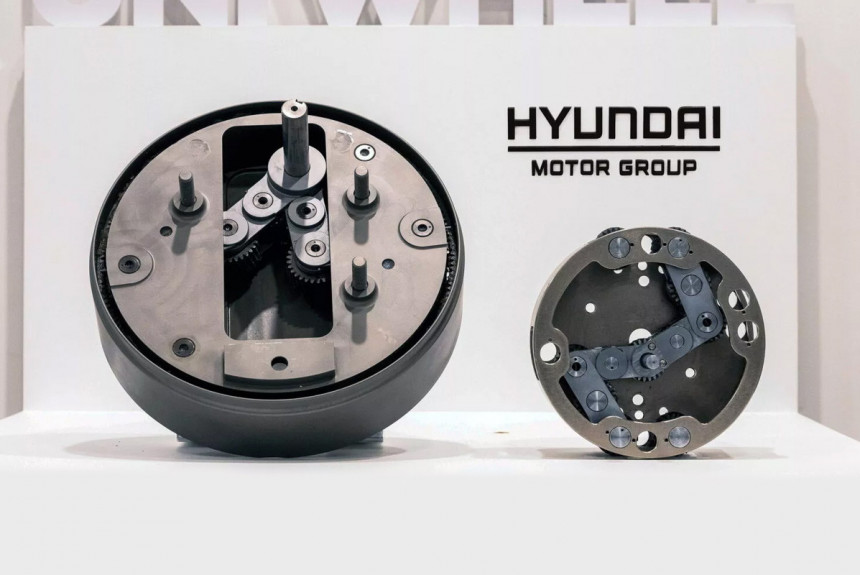

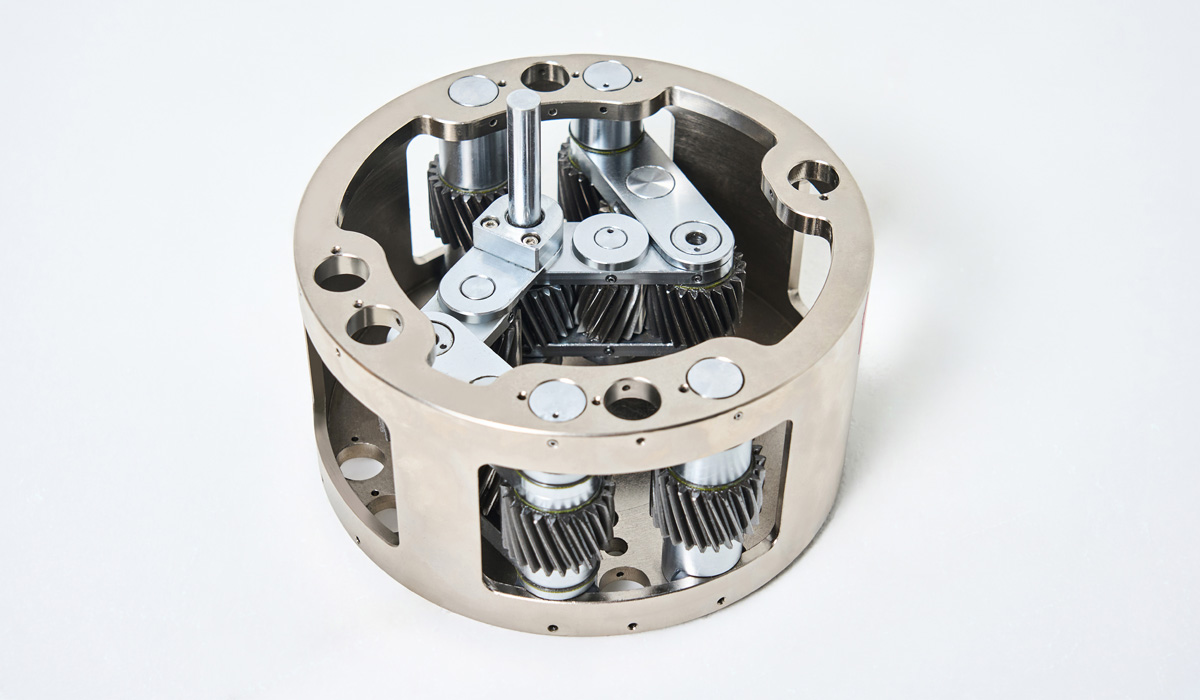

The idea is simple: a heavy electric motor remains on the body or frame, and a relatively light reduction gear is placed in a free space inside the wheel. UniWheel does not have a hinge of equal angular velocities, instead it has a four—link system with a multi-stage planetary transmission: the mobility of this design allows you to transfer torque to the wheel, compensating for the suspension.

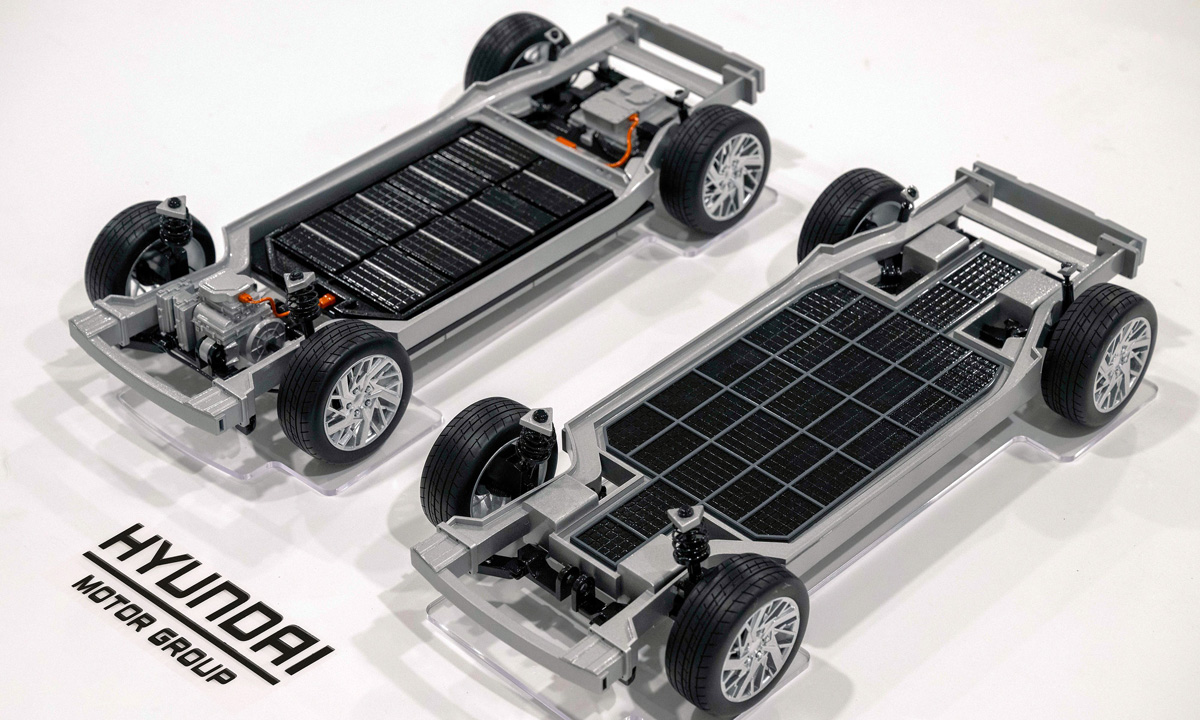

The use of a “gear-wheel” promises a number of advantages. Traction electric motors without bulky gearboxes should become more compact, and together with the use of individual motors for each wheel, this will free up useful space inside the body. Hyundai engineers propose to occupy this space with additional traction battery cells. By the way, individual motors with properly configured control electronics are also a full—fledged thrust vector control system.

On the left — a platform with a traditional drive, on the right — with the UniWheel system

Getting rid of the joints, as stated, will reduce losses when transferring torque to the wheels, increasing efficiency and power reserve. In addition, it opens up the possibility of wider use of the vertical range of adjustment of the air suspension. The UniWheel system can be used with wheels from 4 to 25 inches in diameter, which means the widest coverage of vehicles — from small individual mobility vehicles to SUVs and trucks.

Hyundai stated that it has already conducted a full cycle of strength and resource tests, in which the UniWheel system performed well. It is not yet clear when the innovation node will go into mass production, but it is known that the Koreans have already patented the technology at home, in Europe and the USA, that is, in key sales markets.